Manufacturing the Future Today

Manufacturing the Future Today

We invest in the latest machining technology to ensure superior precision and efficiency. Our commitment to quality is reflected in every component we manufacture, backed by thorough inspection and testing. We understand the importance of deadlines and strive to deliver products on time, every time. Our dedicated team provides excellent customer support, from initial consultation to post-sales assistance. Benefits of our manufacturing services - High precision and accuracy for reliable performance. Customization options to meet unique requirements. Durability and longevity for extended service life. Compliance with industry standards and regulations. On-time delivery and excellent customer support.

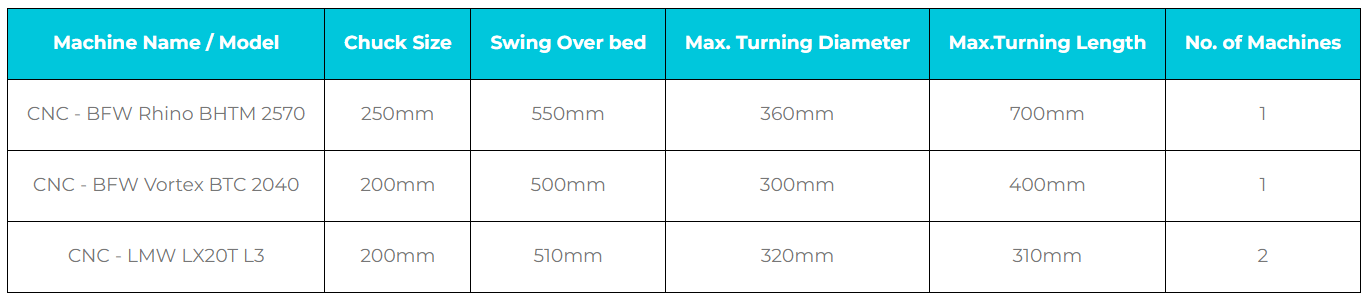

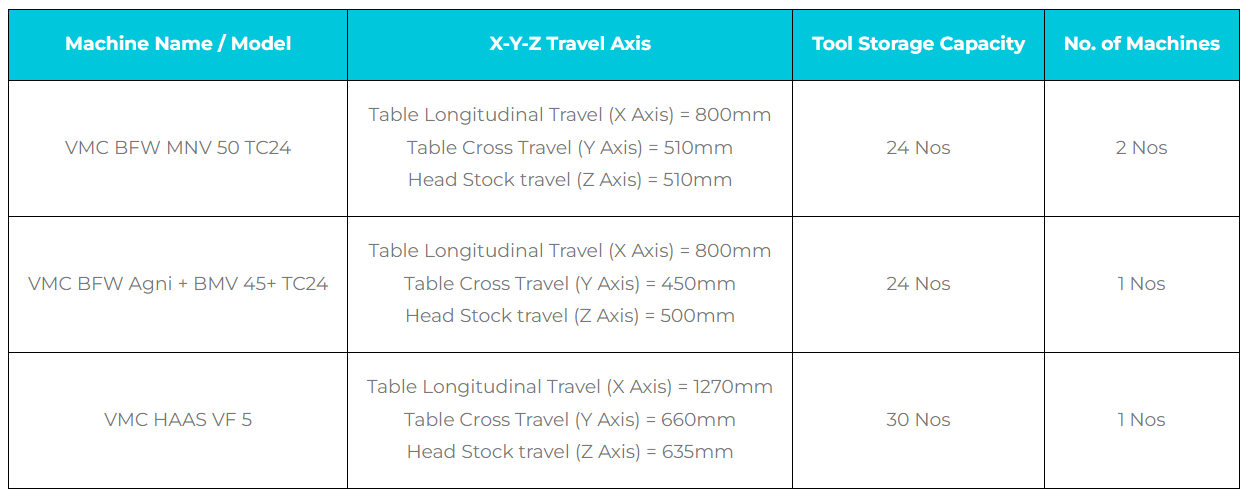

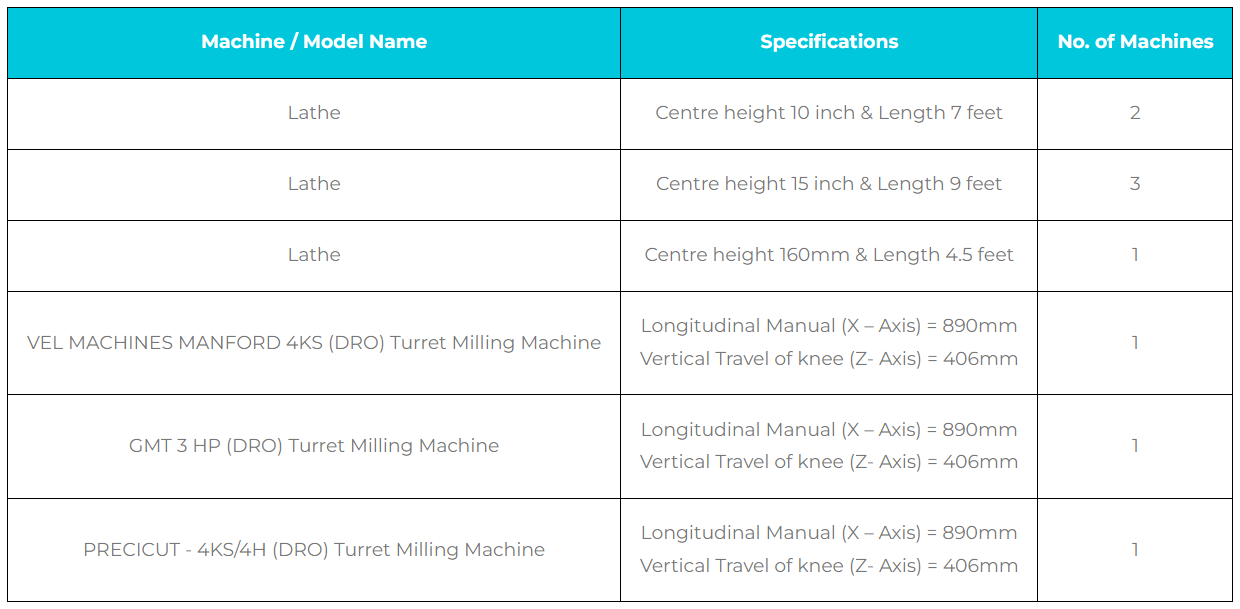

Our manufacturing facility is equipped with state-of-the-art machinery and technology to ensure precision and efficiency in our production processes. We have a range of CNC machining centres / VMC / Conventional Lathes, DRO Milling Machines that allow us to produce complex components with high accuracy and repeatability. These machines are equipped with advanced controls and tooling for optimal performance

Our dedicated quality control lab is equipped with calibrated measuring instruments, tools and equipment to perform thorough inspections on our manufactured components. We adhere to strict quality standards to ensure that every product meets or exceeds customer requirements.

We have a team of highly skilled engineers, technicians, and operators who are trained in the latest manufacturing techniques and best practices. Their expertise and dedication play a crucial role in maintaining the quality and efficiency of our operations. Our facility adheres to strict safety standards and regulations to ensure a safe working environment for our employees.

| Machine Name / Model | Chuck Size | Swing Over bed | Max. Turning Diameter | Max.Turning Length | No. of Machines |

|---|---|---|---|---|---|

| CNC - BFW Rhino BHTM 2570 | 250mm | 550mm | 360mm | 700mm | 1 |

| CNC - BFW Vortex BTC 2040 | 200mm | 500mm | 300mm | 400mm | 1 |

| CNC - LMW LX20T L3 | 200mm | 510mm | 320mm | 310mm | 2 |

| Machine Name / Model | X-Y-Z Travel Axis | Tool Storage Capacity | No. of Machines |

|---|---|---|---|

| VMC BFW MNV 50 TC24 |

|

24 Nos | 2 Nos |

| VMC BFW Agni + BMV 45+ TC24 |

|

24 Nos | 1 Nos |

| VMC HAAS VF 5 |

|

30 Nos | 1 Nos |

| Machine / Model Name | Specifications | No. of Machines |

|---|---|---|

| Lathe | Centre height 10 inch & Length 7 feet | 2 |

| Lathe | Centre height 15 inch & Length 9 feet | 3 |

| Lathe | Centre height 160mm & Length 4.5 feet | 1 |

| VEL MACHINES MANFORD 4KS (DRO) Turret Milling Machine |

|

1 |

| GMT 3 HP (DRO) Turret Milling Machine |

|

1 |

| PRECICUT - 4KS/4H (DRO) Turret Milling Machine |

|

1 |

We work with a metal grade of materials to manufacture components that meet specific performance and durability requirements

| Ref Name | Cast | Bar | Forge |

|---|---|---|---|

| 316/316L | A351 Gr. CF8M/CF3M | A479 Gr. S31600/S31603 | A182 Gr. F316/F316L |

| 17-4PH | A747 Gr. CB7Cu-1 | A564 Gr. 630 / S17400 | A705 Gr. 630 / S17400 |

| 410 | A217 Gr. CA15 | A479 Gr. S41000 | A182 Gr. F6a |

| 31803/Dual | A995 Gr. 4A | A479 Gr. S31803/S32205 | A182 Gr. F51/F60 |

| 32760 | A995 Gr. 6A | A479 Gr. S32760 | A182 Gr. F55 |

| Inconel 625 | A494 Gr. CW6MC | B446 Gr. 625 | B564 Gr. 625 |

| Inconel 825 | A494 Gr. CU5MCuC | B425 Gr. 825 | B564 Gr. 825 |

| Monel 400 | A494 Gr. M35-1 | B164 Gr. 400 | B564 Gr. 400 |

| Monel K500 | - | B865 Gr. K500 / N05500 | B865 Gr. K500 / N05500 |

| 31254 | A351 Gr. CK3MCuN | A479 Gr. S31254 | A182 Gr. F44 |

| 347 | A351 Gr. CF8C | A479 Gr. S34700 | A182 Gr. F347 |

| 32750 | - | A479 Gr. S32750 | A182 Gr. F53 |

| 304/304L | A351 Gr. CF8/CF3 | A479 Gr. S30400/S30403 | A182 Gr. F304/F304L |

| Ferralium 255 | - | A276 Gr. UNS S32550 | - |

| F22 | - | A182 Gr. K21590 | F22 Class 3 & 1 |

| 440 C | - | ASTM A276 S44004 | - |

| Hastelloy B2 | - | N10665 | - |

.png)